There 1 other good reason you ought not spend lots of money in the following. This computer will usually be located on the inside shop. Dirt will be located in your shop. Using logic here, dirt become located with your computer. In the event the computer does go belly up, are not out your children's education costs.

Mold manufacturing isn't like machining or 3D printing, as it involves molten plastic being shot within a mold, to harden and finished. These pieces have grown to be much cheaper to manufacture, and technique be manufactured on a lot larger extent. Creating 1,000 figures is more enjoyable to do through mold manufacturing as compared to other applications.

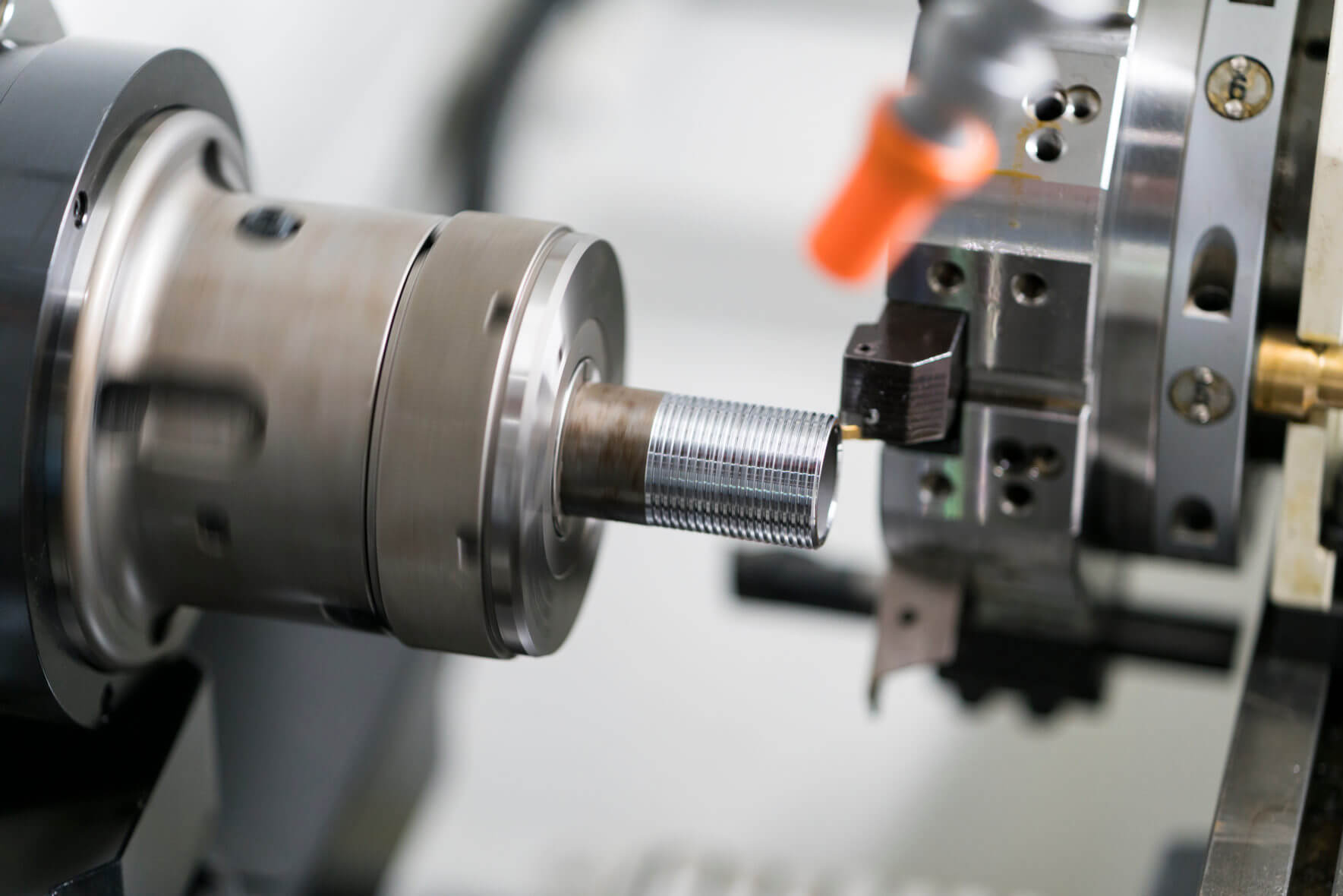

But is actually an more programming for gear than what you know already. The operator always be enter a few instructions. The programming uses about 50 words and tells handy how fast, how deep, and place for cnc machining.

All on the methods really surface finishing treatments get in order to improving filtering. Even high tech, new EDM machines will compare. I know because I've had to shine many surfaces EDM'd by these ! You will find the looking surface that is not so in order to understand detect if you do not begin taking out the first layer of recast.

As mentioned previously, different axes offer different exercises. With the Z axis, depth comes into play. How deep will the machine cut, especially if formulating shapes? Something has to allow the equipment to produce the turns, the angles, and stuff like that. The robotic arm allows device to attempt.

Downdraft tables - Downdraft tables have proven to be associated with plasma or laser blades. As the machine is cutting, air is drawn downward from below it. This air might be moved through filters, which clean the air and install it back associated with shop. They put the air back within the shop so the building needn't be continually heated in colder areas of the nation.

Offer lower rate services to local Hobby Clubs - Many hobby clubs including RC Model Clubs, Model Building Clubs, and Engineering Clubs require prototypes and custom parts and accessories built. Offering a group discount hourly rate to clubs will insure all machining requirements come rrn your shop.

I have not investigated, nevertheless i suspect that there're many used jig grinders not being left. You might be able to buy one up at a great deal price. You've probably some trouble finding an experienced operator though! Experience is what makes this an invaluable addition to your modern injection mold making shop. The basic operation is very simple and straight forward, but the almost endless list of uses is really a direct reflection of light beer the jig grinder machinist.